Article

A Decade of Development at Curraghinalt

2025 marks 10 years since Eric joined the Dalradian team as Chief Operating Officer. What began as a 2-year project turned into a defining chapter of his career.

“When I first joined the team, my mission was to complete the test-mining programme and a feasibility study to support the permitting application, about a 2-year project. Once that first mission was accomplished and I could see the full potential of the project, I was keen for my next mission – optimising the mine and helping to secure the permit.

Eight years later, we are nearing the end of the permitting process. While it has taken longer than expected, that has given us many opportunities to further improve our plans. We’ve been able to incorporate the latest technology as it develops, and carry out further research to better understand the conditions underground. By updating the mine plan and adding ore-sorting technology, we’ve been able to increase the production of the mine by about 60% without adding to the small surface footprint.

Our engineering team also made some changes to the project based on feedback received during the permitting process – such as moving some of the processing underground, reducing the energy requirements, committing to carbon neutrality, changing the processing to remove the use of cyanide and contouring the dry stack so that it fits in well with the rolling hillsides of Tyrone.”

So, what drew him to this project? For Eric, it was the combination of opportunity, people, and place.

Before Eric came on board in 2015, he was enjoying working for Agnico Eagle, one of the top mid-sized mining companies, and he was not looking to move. Patrick Anderson, Dalradian’s CEO, invited him to do a site visit. “When I saw how great the project was, I realised I was ready for a new challenge.” Dalradian’s project in County Tyrone was unique, unlike anything he had worked on before, and gave him an opportunity to combine his decades of experience in mine building, permitting, and community relations with the chance to learn something new.

“What attracted me was the bigger picture,” Eric recalls. “I’d spent much of my career building mines and working closely with communities, but this project also gave me the chance to understand the financing side and how the market works. That was new for me—and exciting.”

And then there was Northern Ireland itself “It was my first time here, and I thought, what a beautiful place to work and live. I saw potential and wanted to take my knowledge and help create something lasting —something that could be one of the best projects ever.”

Fire in the Hole!

Eric joined as the underground exploration programme was in full swing, with the permits for the test mining received in 2014.

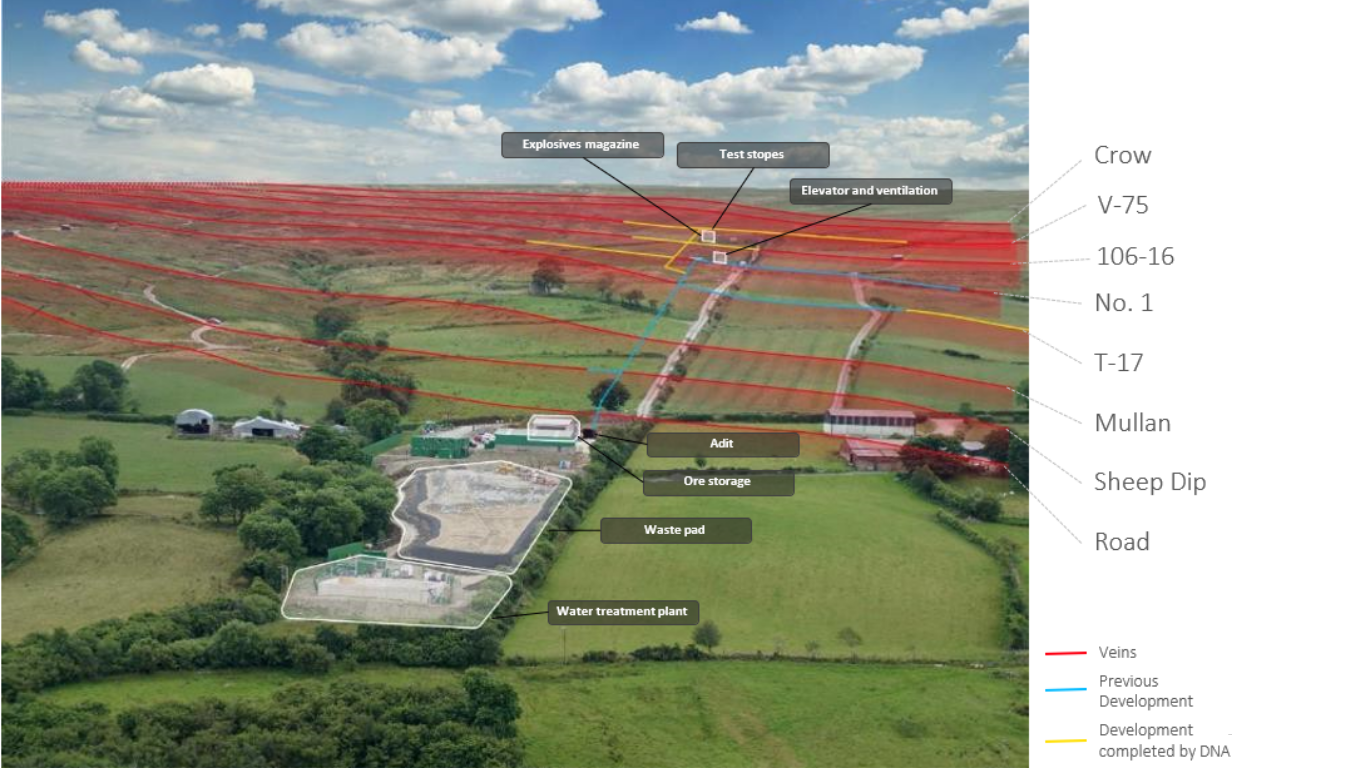

In 2015, blasting was happening almost daily, and more than 900 metres of tunnel were added by QME, our mining contractor from Navan to the already existing tunnel from the 1980’s. QME are one of the main mining contractors at Tara Mines.

These tunnels exposed more of the mineralised veins, giving the team direct access for sampling and further exploration, including underground drilling. From the development tunnels, the miners were then able to blast down between levels to take out 3 panels of mineralized rock or “stopes”.

That allowed the mining team to observe how the rock responded to blasting. What they observed was very positive: the rock split cleanly, without excessive over-breaking and minimal ground support was needed after the blasting to keep the rock in place.

More than 15,000 tonnes of ore from the programme was shipped to an existing processing facility in North America to reconcile the actual amount of gold recovered from those 3 test stopes and the ore tunnel development compared with what was predicted by the 3-D geological model of the deposit that had been built up from drilling and sampling data. “The results were much better than expected, said Eric. We recovered 42% more gold! Not because we had built a bad model from our exploration drilling, but because, in addition to the large main veins which were in the model, there were many small veinlets that couldn’t be modelled. It turns out those add a lot more gold than anticipated.”

“The goal was to de-risk the project, in terms of geology, mine design and engineering” Eric explains. “With narrow vein deposits, key aspects are continuity of the veins and dilution control (minimising the amount of unmineralised rock that gets added to the ore). Drill holes give you an indication of what’s there, but they tend to be separated by tens of metres, so you need to open it up underground to prove the veins continue in between. That’s what we set out to do—show that the project was both technically solid and economically viable. We proved that conventional mining methods worked very well at Curraghinalt and that the veins are continuous and predictable, this information fed into our planning application”

In addition to the test mining, the permits also covered a water treatment plant, explosives magazine and a waste rock store, which was fully rehabilitated at the end of the programme. The water treatment plant has been kept in place to treat the small amount of water that is still flowing out of the tunnels.

In addition to the technical data, the programme yielded an important side benefit, “Over 1,800 people have been able to visit the project, go underground and see how a modern mine works,” commented Eric. “We’ve had school groups, farmers, local residents, politicians and even engineers working in Tyrone to design and build underground mining equipment. Believe it or not, most of those engineers had never been in an underground mine! It gives people a chance to meet us, ask questions and see for themselves what the proposed project is about. In the future, it could serve as a training ground for miners using actual mining equipment in addition to the training they will do with simulators and virtual reality. It would also make a tremendous visitor centre for tourists interested in having an underground adventure.”

Building a Super-Team!

For Eric, the technical side of mining was only one part of the challenge. Just as important was building the right team.

“When I arrived, there were geologists and engineers from all over the world. My focus was to bring the team together and, over time, ensure more roles were filled by people from the local community. That’s always been the long-term vision—that the project creates opportunities here in Tyrone.”

At its peak, the project employed more than 130 people, either directly with Dalradian or through our Irish contractors - QME for the mining and Priority for the surface drilling – and international contractor – Major, who did the underground drilling. A strong focus was placed on hiring locally, with training provided to help people step into new careers as drill helpers and drillers. Many of those who started their journey with us have since progressed and continue to work as drillers today all around the world. For specialist roles that couldn’t be filled locally, workers stayed in the area—supporting pubs, restaurants, and local services, which boosted these local businesses.

From Test Mining to Planning

The programme of work finished in 2016 and the results when on to inform the economic feasibility study which included a detailed mine plan, equipment list, manpower list and demonstrated that the project was economically robust.

“We knew the market wanted a project with strong returns. To get there, we had to do the groundwork—drilling, testing, modelling. It was a team effort, with Patrick raising the funding, Greg Hope leading the geology, and experienced miners like Bernie Harradine bringing decades of expertise. Bernie grew up in Cornwall and has worked all over the world as an underground miner, he said our project was the first time in his career that he was able to work back close to home since the mines in Cornwall closed. Together, we moved the project forward step by step.”

The exploration, engineering and mine plan, along with substantial environmental studies over many years, informed development of Dalradian’s planning application, which was submitted to the Department for Infrastructure in 2017.

A Decade of Progress

Looking back, Eric sees his time at Dalradian as both challenging and rewarding. What began as a two-year commitment grew into a decade of progress, teamwork, and a journey through the planning system. Over the 10 years he worked with fantastic people who became friends.

“Projects like this aren’t built overnight. They take vision, persistence, and the right people. I’m proud of what we’ve achieved and excited for what’s ahead. The Curraghinalt deposit is truly one of a kind—a unique opportunity to build a world-class project that will bring many benefits to the local community and beyond.”

Watch the first blast underground from Dec 2014 - https://www.youtube.com/watch?v=3Q_4uQxsxFU

Watch the rehabilitation of the waste rock storage rock - https://www.youtube.com/watch?v=1HmR2Qx8vkg

Your support matters

Support our plans to create jobs, strengthen the local community and respect the environment. The Department for Infrastructure will take your views into account. Help make our plans a reality.

Your letter of support will be sent directly to the Department for Infrastructure. Dalradian will not see your letter, nor any of your details.

Great things can happen with your support

Support our plans to create jobs, strengthen the local community and respect the environment. The Department for Infrastructure will take your views into account. Help make our plans a reality.

Customise a letter of support in two simple steps:

Provide your personal details

This will signal your support to the Department for Infrastructure. You can choose to keep these details private.

Tell the Department for Infrastructure why you support the project

Please tick all the elements you like about the proposed project.

Dalradian will not see your letter, nor any of your details. Your letter of support will be sent directly to the Department for Infrastructure